Experiment to Produce A Spinning Electromagnetic Field

in a Cylindrical Cavity

Mode and Frequency

Used

On

this page are details of the method used and the

results obtained when carrying out the experiment to produce a spinning

field.

Also described are the problems encountered, so if you wish to carry

out

similar work I hope this information will help avoid some of the

potential

difficulties. The cavity used was chosen to be resonant in the 70cm

amateur

radio band which covers 430-440MHz and for which a transmitting license

was

available. The cavity was of cylindrical form as this was easier to

construct

than a sphere and was intended to be resonant at 435MHz in the centre

of the

band. It was decided to use a TM mode, so the lowest frequency spinning

mode

(TM110) was selected as this allowed the physically smallest size of

cavity to

be constructed. If a TE mode were used TE111 would be even smaller and

have

fewer possible interfering modes although the required measuring probe

positions would be different from those described here. The resonant

frequency

of the TM110 mode is independent of the cavity height so the diameter

can be

chosen solely for resonance at the desired frequency and works out to

84.06 cm

diameter. (See Tables of Cylindrical Cavity

Resonant Modes

for the formula used). As the resonant frequency of many of the other

modes

also depends on the cavity height it is important to choose a height

which does

not bring another resonance near to the desired one as this would make

setting

up extremely difficult. The resonant frequencies of the other modes for

the

cavity used are also shown in the Tables of

Cylindrical

Cavity Resonant Modes. Mode charts are available which show

graphically all

the resonant frequencies of a cavity and these are ideal for a rapid

frequency

selection if a different frequency is to be used. A typical Mode Chart

is shown

in Fig 30 below:-

In

this case a height of 50 cm was chosen as this

gives a ratio of diameter to height of around 1.68 ( ![]() = 2.82

) and is clear of other modes as shown by the “X”in

the above

chart.

= 2.82

) and is clear of other modes as shown by the “X”in

the above

chart.

Cavity Construction

The

cavity was fabricated from 18 s.w.g. half hard

copper sheet. The maximum length sheet available was 8ft (2.44metres)

which

meant that in order to give the required 2.64 metre circumference a

join was

necessary. For this a butt joint was used with an exterior 18 s.w.g.

backing

strip just 1.3 cm wide added for strength. It was decided to braze the

cavity

using high silver content brazing alloy. This was done in order to give

minimum

cavity losses and maximum Q. Before brazing the cylinder joints were

bolted together

and end plates temporarily held in place so that a check of the

resonant

frequency could be made. It appeared that the frequency was about

2.5MHz too

low so 1.6 cm was removed from the circumference to bring the frequency

back to

435 MHz. It was subsequently realized that it was the poor bolted

joints that

had caused the frequency reduction and it would have been better to

have

constructed the cavity to the exact calculated size. Fortunately even

with the

reduced diameter of 83.4 cm the cavity was still resonant within the 70

cm band

at just under 438MHz.

At

the required brazing temperature of 6500 C,

copper of this thickness goes very pliable and will not hold its shape

when

heated. As the gap for a brazed joint must be kept between say .02 -

.15 mm it

was necessary to rivet the joints at least every 5 cm using copper

rivets. The

circular cavity end plate was annealed and given a 1cm flange by

bending the

edges around a circular wooden former. The end plate was riveted in the

cavity

prior to brazing. After brazing it was necessary press the wooden

former

through the cylinder to maintain the cavity’s circularity. For anyone

wishing

to construct a similar size cavity I would suggest soft soldering as

this could

be done using temporary clamps instead of rivets as the soldering

temperature

is lower and the joint gaps are not so critical. The end plates could

be left

flat and soldered straight onto the cylinder ends without the need for

a flange

as the copper would distort much less. Also the copper would not loose

its

hardness at soft solder temperature which would help keep it circular.

To keep

the Q high just keep the joints as tight as possible and remove any

surplus

soft solder from inside the cavity.

Despite

having gone to such lengths to get maximum Q

it was finally decided to only braze the bottom cylinder end plate and

at the

other end a flat copper plate was just placed in position on top of the

cavity.

To make better contact it was weighted down all around the edges with a

total

of 50 kilo in weight. The loose end plate was initially used in order

to

maintain access to the cavity for fitting probes and as it did not give

any

major problems it was then left like that (so much for the high Q

construction!!). The theoretical Q for a cavity of this size is about

50,000

and a loaded Q of 20,000 was actually measured which is adequate for

this

particular experiment.

Measuring Equipment

Initially

the cavity was energized in the conventional

stationary mode. A Yaesu FT-100 transceiver was used which provided a

12 watt

radio frequency (r.f.) power source of high frequency stability and

with a

built in digital frequency readout. This source fed a small 4.5 cm

diameter

copper wire loop projecting into the cavity half way up the side.

The r.f. was fed through the cavity wall using a 50 ohm BNC

socket onto

which the loop was directly connected. By not quite fully tightening

the BNC

socket it was possible to rotate it and the loop from outside the

cavity. This

provided a very useful means of matching the loop impedance to the r.f.

source

as the effective area of the loop is the area that is normal to the

magnetic

field and the loop impedance is proportional to the area of the loop

squared.

For the modes used in these tests the maximum loop impedance is with it

positioned vertically and as it is turned to the horizontal the

impedance falls

to a low value.

For

the TM110 mode the maximum value of electric field

occurs at a distance of half the cavity radius away from the cavity

centre

axis. A ring of probes was therefore placed in the top cylinder end

plate on a

circle about the cavity centre (the circle being the same diameter as

the

cavity radius). The probes were positioned at 45 degree intervals

around the

circle. Each probe comprised a 3 cm length of copper wire connected to

a BNC

socket which provided the feed through the cavity top end plate. The

voltage on

the probes was measured using a Tektronix 2445A, 150MHz oscilloscope.

Unfortunately a higher bandwidth oscilloscope was not available but

tests showed

that although both channels suffered a 10 times reduction in

sensitivity at

440MHz, deflection was linear provided 60% deflection was not exceeded.

The

phase shift difference was within 0.18nSec and constant and unaffected

by

changing input voltage amplitude within this range. So, although not

ideal,

this instrument was adequate for the measurements to be made provided

it was

operated within the voltage limitations and the constant phase error

allowed

for. This instrument did have the advantage of having four channels.

Two of

these were of limited sensitivity and had different calibrations from

the main

channels at 440 MHz so they were not used for measurement. However,

they were

still useful for monitoring the voltage on extra probes which assisted

in initially

setting up the rotating field.

It

was found that use of the standard x10

oscilloscope probes was not possible due to signal pick up which gave

totally

unreliable readings. Instead a number of small metal boxes, each fitted

with a

BNC input plug output socket were made. An 82kohm resistor was fitted

in each

box, connected between input and output, to reduce the oscilloscope

loading. It

was found that fitting one of these isolation boxes to a cavity probe

significantly detuned the cavity but fortunately connecting the

oscilloscope to

an isolation box output did not further affect the cavity. Because of

this

eight isolation boxes were made and one connected to each cavity probe.

These

boxes should be identical and low tolerance, matched value, carbon

resistors

used. Connection from these isolation boxes to the scope was with about

a metre

of 50 ohm RG58C/U coax cable fitted with BNC connectors. Four coax

cables were

used and all cables were initially made the same length. The cables and

isolation boxes were numbered and a particular cable and isolation box

was used

only with an assigned oscilloscope channel. The lengths of the cables

were then

adjusted slightly so that all oscilloscope channels gave identical

phase

readings. Measurements could then be made on a probe by swapping its

isolation

box for one with a monitoring oscilloscope channel attached and this

would have

a negligible effect on the cavity tuning. Using screened connections

and leads

throughout in this arrangement gave fairly stable and repeatable

voltage and

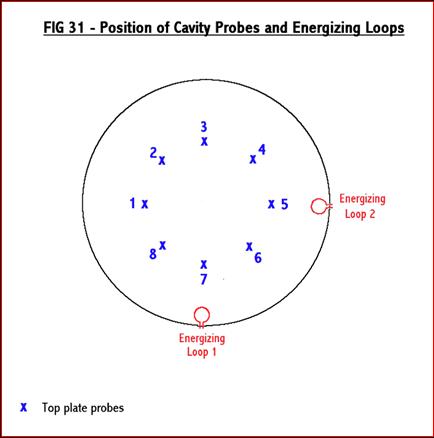

phase readings. The numbering used for the cavity probes and

energizing

loops is shown in a plan view of the top of the cylindrical cavity in

Fig 31

below. This also shows the second energizing loop which was used for

the later

spinning field tests:-

Tuning The Cavity (Conventional Mode)

To

tune the cavity the r.f. source frequency was

adjusted to give maximum oscilloscope deflection with the oscilloscope

connected via an isolation box to the cavity end plate probe number

three,

positioned opposite to the input loop. Only input loop 1 was fitted for

these

experiments and it was turned for best matching of the 50 ohm r.f.

source to

the cavity. This was determined by measuring the standing wave ratio

(SWR)

between the source and the loop using a cheap commercial SWR bridge. It

is

necessary to retune the r.f. frequency for maximum oscilloscope

deflection each

time the orientation of the loop is altered as turning the loop even

slightly

detunes the cavity. Best match was an SWR of about 2.0 and usually

occurred

with the loop turned about 20 degrees from the vertical for the 4.5 cm

diameter

loop. From theory the loop should have a low inductive reactance and

that is

why a 1.0 SWR is not obtained. It was found that if the r.f. source was

tuned

slightly away from peak oscilloscope deflection then a 1.0 SWR could be

obtained. In this condition the cavity is being tuned off resonance and

the

cavity reactance produced as a result of this is tuning out the loop

reactance.

However, a 2.0 SWR was perfectly adequate and was considered preferable

to

having the cavity detuned. Because of this most tests were carried out

with a

reduced power of only 2.5 watts in order to protect the source from the

high

r.f. voltages which can arise with a raised SWR. This still gave

sufficient

signal for measurement and also protects from the high SWR which

results if the

cavity is further mistuned. It would be possible to get a lower SWR by

using a

matching circuit but the additional complication was again considered

unnecessary at these power levels.

For

a small coil the magnetic field is a maximum

passing through the centre of the loop. However, there is also a

magnetic field

produce at right angles to this off the sides of the loop. As the size

of the

loop is increased the proportion of field off the side increases

relative to

the field through the centre. These two loop fields energize the same

cavity

mode (ie TM110 in this case) but the two modes are at right angles to

each

other. If the cavity is not exactly circular the two modes will have

slightly

different resonant frequencies and the two resonant peaks in the cavity

probe

voltages may be observed. The main mode being measured here has a

maximum

electric field adjacent to the loop (i.e. probe 7) and also 180 degrees

around

the cavity diameter from this (i.e. probe 3). This can be checked by

measuring

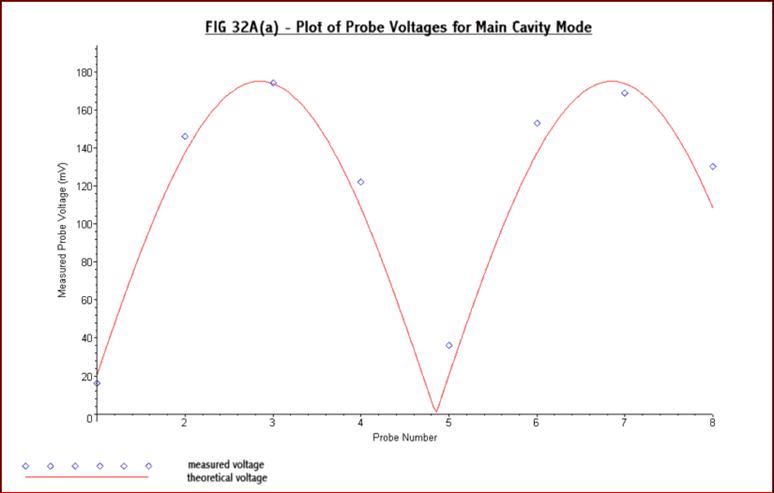

the voltage on all the cavity end plate probes. In all tests the peak

to peak

voltage was measured on the scope and is what has been used in the

typical

results shown below:-

Fig

32A(a) also shows the theoretical shape of the

voltage readings it would be expected to obtain at the cavity probes.

It has

the shape of an |A sin(ф-ε)| curve where ф

is the phase angle around the cavity measured from the

point of minimum field and the amplitude (A) and phase error (ε) have

been

selected to best fit the experimental results. Each probe is spaced 45

degrees

so the phase error can be obtained from the zero of the best match

theoretical

curve, which is at 4.85 instead of 5.00, so the error is 45 x (5.00 –

4.85) =

6.75 degrees. It could be due to misalignment between the end plate

probes and

the energizing loop. However it is most likely due to a small voltage

being

present from the field off the end of the loop which is adding to the

main

field and altering the null position. Apart from this the measured

voltages are

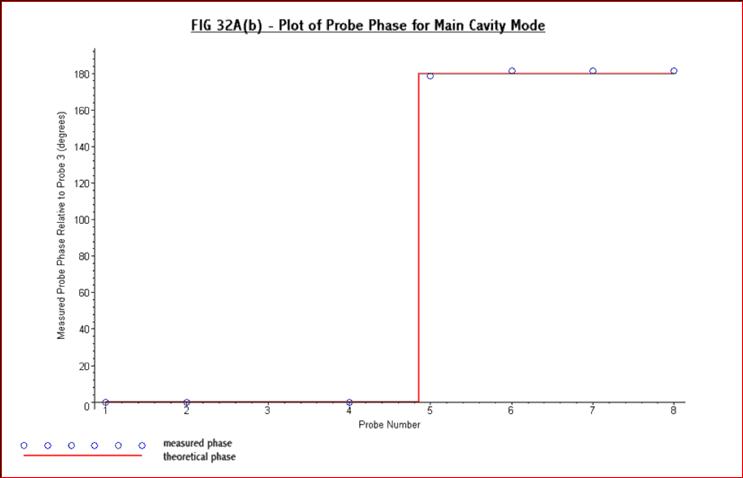

in reasonable agreement with the theoretical values. The frequency was

438.39870MHz. Fig 32A(b) below is the plot of the phase measured

between

probe 3 and each of the other probes. This was obtained by measuring

the time

difference in reaching the peak voltage and this is also as expected

for a

TM110 cavity mode:-

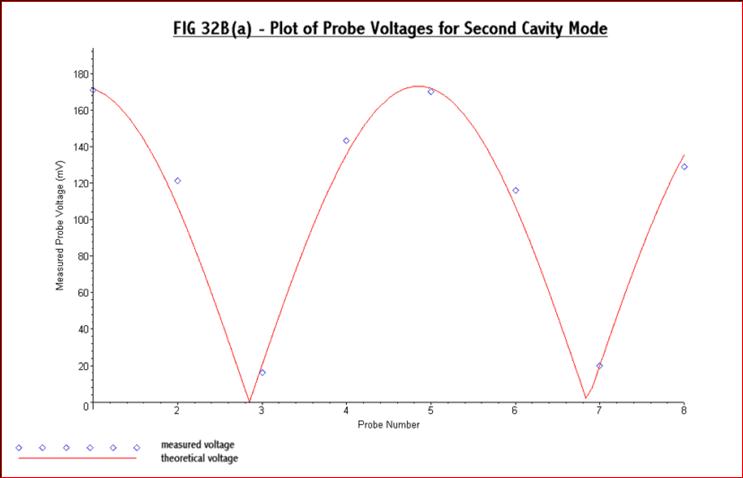

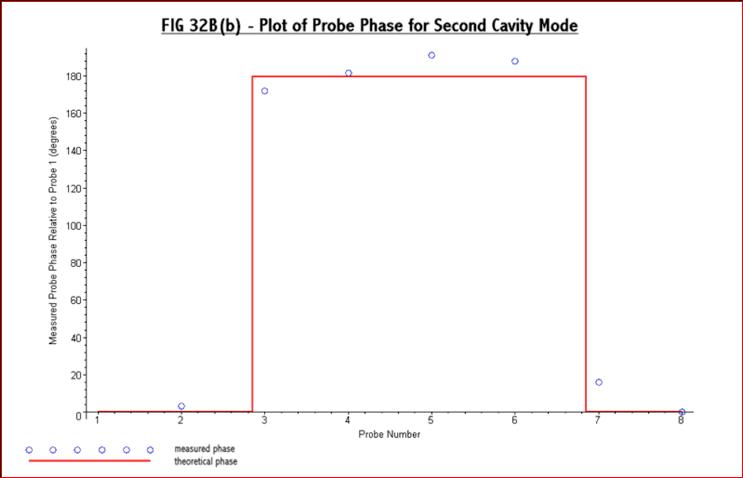

If

the cavity is tuned to the second mode which is

being energized by the field off the end of the loop this will be when

the

field at the probes 90 degrees from the loop (probes 1and 5) is a

maximum. In

this case it was at a frequency of 437.3621 MHz, just over 1 MHz below

the main

mode. Depending on the shape of the cavity it could easily have been up

to 1

MHz or more above. A typical set of peak to peak probe voltages and

phase

readings is:-

The

theoretical voltage curve is now of |A'

sin(ф-90-ε)|. Despite the phase measurements not fitting the

theoretical curve so well the readings clearly confirm that the

theoretical

TM110 mode is still being energized and that it is at right angles to

the

previous main mode. In this case probe 1 was used as reference as probe

3 has a

low voltage so it would be more difficult to take accurate phase

readings to

this probe without switching ranges on the oscilloscope which was not

permissible. The SWR for this mode was 5.5 and was with the coil

vertical which

indicates that there is a poorer impedance match. However, even so, the

maximum

cavity probe voltage was almost identical to that obtained for the main

mode.

It

was found that both modes went to a minimum when

the energizing loop was rotated to the horizontal position. This

provided a

useful means of confirming the loop position when the cavity was

completely

assembled.

How

to Produce the Spinning Mode in the Cavity

The

standard method of producing a rotating field is

to use two energizing loops spaced 90 degrees apart around the

circumference

and fed with signals time displaced 90 degrees. This is similar to the

way a

two phase motor produces a rotating field. It is just as applicable at

r.f.

frequencies and is the best method found to produce a purely spinning

field.

The voltage plots in Fig 32A and 32B for the single loop stationary

modes

confirm that the field in the ф direction is sinusoidally distributed

and

it is also known that it is varying in amplitude sinusoidally. We can

show

mathematically that a spinning field is produced by writing the field

from the

single loop as:-

E1 = F.![]()

Where

F is a function representing the field

distribution in the radial and z (height) directions. NB. The

expressions used

for the phases are just representative, no attempt has been made to

match them

to actual loop positions used.

If

there is another loop 90 degrees apart around the

circumference and the current is 90 degrees phase shifted then the

field from

this loop will be:-

E2 = F.![]()

The

combined field with the two loops energized will

be the sum of these two fields:-

Et = E1 + E2 = F(![]() +

+![]() )

)

Using

the standard trig relationships:-

2cosAcosB

= cos(A+B) +cos(A-B)

and

2sinAsinB=cos(A-B)-cos(A+B)

This

gives:-

Et = ![]() (cos(ф-ωt)

–cos( ф+ ωt) + cos( ф+ ωt) + cos(ф-ωt))

(cos(ф-ωt)

–cos( ф+ ωt) + cos( ф+ ωt) + cos(ф-ωt))

= F

cos(ф-ωt)

(1)

In

some respects this is just a different way of

writing the addition of two stationary fields but it also represents a

completely new field system which is physically spinning in the +ф

direction. The reality of the spinning field in the similar two phase

motor

case is apparent from the rotational speed and torque developed by the

motor

and is just as real, although not so obvious, in this r.f. field.

The

simplest way to produce the required current phase

difference is by feeding the two loops in parallel and using a quarter

wavelength longer feed line to one of the probes. Ideally, if the loop

impedance is 50 ohm then connecting them in parallel would present the

r.f.

source with a 25 ohm impedance. However, a quarter wavelength of 75 ohm

line

will convert a 50 ohm impedance to 100ohms so this was used in each

loop feed

line to convert the loop impedance to 100 ohm so the parallel impedance

would

be 50 ohm. A diagram of the phasing line used is shown in Fig 33 below:-

The

phase delay produced by a length of line does not

normally just depend on its length as the reactive impedance of the

load also

affects it considerably. Fortunately for lines which are exact

multiples of a

quarter wavelength, such as are being used here, the phase delay is

independent

of reactive impedance. If the two loops have the same reactance the

extra

quarter wavelength in the loop 2 line will convert it’s reactance

from

inductive to capacitive so when the two are connected in parallel there

will be

a tendency for the reactances to cancel, although not normally exactly.

However, this is the ideal case and one problem is mutual inductance

between

the loops and this will be opposite for each loop as the voltage from

one loop

will be in phase by the time it reaches the other but the voltage

from

the other loop will be in antiphase at the other. It was thought

that

this might be a problem and in practice the best spinning field was

obtained by

tilting the two loops to different angles so the above theoretical

perfectly

matched condition was not used. However, using this phase delay line it

was

found possible in practice to adjust the currents in the loops to

obtain a

spinning field provided an SWR of about 2 was acceptable at the r.f.

source,

which it was.

A

quarter wavelength in free space is about 70/4 =

17.5 cm long. This is not the length required for a quarter wavelength

of

coaxial cable as the wave in the cable only travels at about 0.65 of

the free

space velocity. This is known as the velocity factor and varies

depending on

the cable construction. A quarter wavelength of coax is therefore

approximately 17.5x0.65 = 11.4 cm long. Experimental methods to obtain

an exact

electrical length of coax cable rely on the fact that an open circuit

quarter

wavelength of line (also ¾, 1¼…etc wavelength) will appear to be a

short

circuit if the impedance is measured at one end. Conversely a short

circuited

half wavelength (also 1, 1½, 2…etc wavelength) of cable will appear to

be open

circuit if the impedance is measured at the opposite end to the short.

If you

have an r.f. impedance bridge you can measure the cable impedance

directly. If

not there are various simple techniques available which make use of

these

characteristics. The main error is due to additional impedance caused

by the

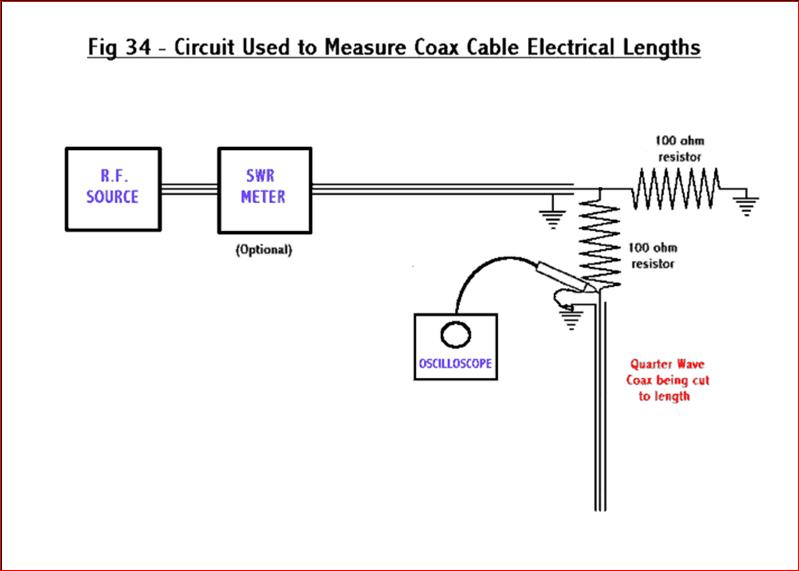

measuring system and cable terminations used. The method adopted here

was with

the r.f. source, set to the resonant frequency of the cavity, used to

apply an

r.f. voltage to the cable under test. The test length of cable was

energized

through a resistor network so that when the cable was a quarter

wavelength long

the voltage across it, which was monitored using the oscilloscope,

would be a

minimum. The circuit used is illustrated below. The two resistors

ensure the

source always feeds into a reasonable SWR load:-

The

earths were connected to a small copper plate and

made as short as possible and the resistors were carbon. The coax line

under

test is cut, removing about 3mm at a time and the voltage on the scope

recorded

each time. The minimum voltage will be reached when the line is a

quarter

wavelength long. It is likely you will overshoot first time but the

required

length will now be known. The same technique can be used to find a

¾

wavelength. (and if it’s not three times the length of the quarter

wavelength

cable you have a problem with the technique!). Half wavelength could be

found

by repeating the procedure but with a short circuit on the far end of

the line.

However due to the inconvenience of fitting the short it is easiest to

just use

a cable twice as long as the measured quarter wavelength.

Tuning the Cavity for

the Spinning Mode.

To

tune the cavity the two loops are first energized

using the phasing line and the voltage on cavity probes one and three

monitored

on the oscilloscope. If the r.f. source frequency is adjusted either

side of

the calculated cavity resonant frequency it is likely that two peaks

will be

observed on the oscilloscope. These will be the main and second modes

measured

above. To bring the two resonances to the same frequency a substantial

octagonal

wooden frame was built around the cavity. This nominally touched the

cavity in

eight places around the diameter although the frame was constructed

slightly

oversize so that there was about 2mm clearance between the frame and

the cavity

at these points. The frame was fitted with four simple screw jacks each

with a

vertical load spreader bearing against the top half of the cavity

circular

sides at 45 degree intervals around the periphery. Two were on the same

axis as

the two energizing loops, one midway between them and one 45 degree

away (i.e.

adjacent cavity probes 4,5,6 and 7). The load spreaders were simple

hardwood

strips about 23x5x0.7cm, each with wooden block about 5x5x2cm attached

which

had a hole drilled through it to locate the screw of the jack. Four

notches

about 5.5x1cm each were cut in the octagonal frame to make room for the

load

spreaders. This arrangement is shown in Photographs

1, 2

and 3.

Adjusting

the circularity of the cavity with the screw

jacks allows the main and second resonant peaks to be brought to the

same

frequency. The tilt of the loops can then be adjusted until the

voltages on the

cavity top plate probes are as identical as possible and the phase

difference

between each adjacent probe is 45 degrees. This is the condition which

is

required for a spinning field to be produced. For this adjustment it

was useful

to have the two additional oscilloscope channels available which were

temporarily

connected to probes 2 and 4 to approximately confirm that the voltage

and phase

here appeared to be correct before a full set of all probe readings

were taken

using the two calibrated oscilloscope channels. To reach the correct

condition

requires repeated small adjustments to the r.f. frequency, cavity

circularity

and loop angle as the adjustments are very critical and inter-related.

Because

the cylinder top plate was not soldered in position the tuning could

also be

disturbed by a change in top plate contact resistance particularly as

the

cavity top plate probes were interchanged to take scope readings. So

after

taking a complete set of readings the initial probe readings were again

checked

and if these had changed significantly the results had to be discarded

and a

new set of readings taken. An example of typical readings obtained is

shown in

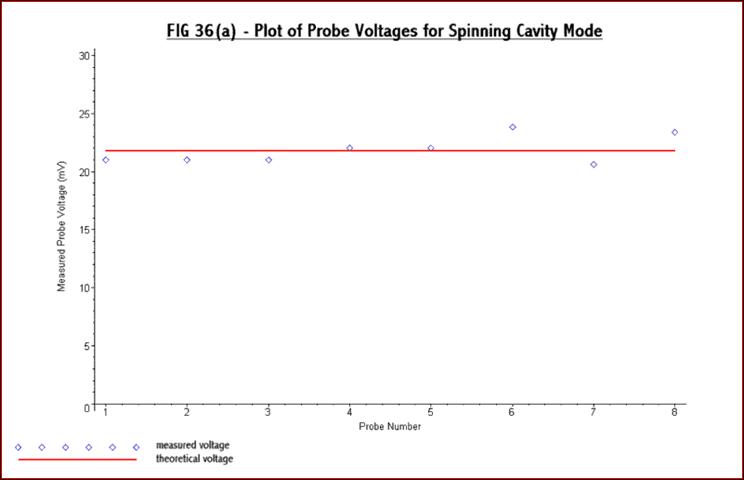

Figs 36(a) and 36(b) below:-

Although

the probe voltages are not quite identical

the results are in reasonable agreement with theory and indicate that a

spinning field has been produced in the cavity. This is the best

technique

found for producing a pure spinning field in the cavity.

Effect of Change in

Phase or Amplitude in the Field of an Energizing

The

affect of tuning the cavity can be analyzed

mathematically using a similar method as was done previously. If we

consider

just the main mode field and assume that these fields from the two

loops have

different amplitudes and a phase difference between them which is not

exactly

90 degrees then the equation for the field from loop 1 is:-

E1 = F.![]()

Where

F is again a function representing the field

distribution in the radial and z (height) directions.

If

the current in loop 2 is 90 degrees phase shifted

then the field from this loop will be:-

E2 = F.A.![]()

Where

A is the ratio of the field amplitudes and a

represents the phase error from the correct 90 degree phase difference.

The combined field with the two loops energized will be the sum of

these two

fields:-

Et = E1 + E2 = F(![]() +A

+A![]() )

(2)

)

(2)

The

variation of Et with time at different cavity top

plate probes (ie values of phi) can be plotted for various values of A

and a.

First assuming the phase difference is constant at 90 degrees (ie a

is zero) the effect of a change in A, the relative amplitude of the

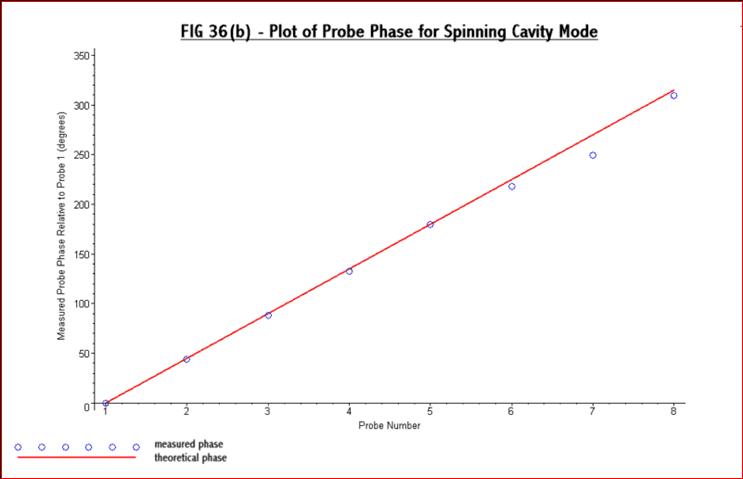

current through one of the coils is shown in Fig 37:-

It

can be seen from these plots that with equal field

amplitudes from the two loops the voltage measured at all the top plate

cavity

probes will be the same and the phase difference measured between them

will be

the same as their physical angular separation (i.e. 45 degrees in this

case).

This is the purely spinning field which was also created experimentally

as

shown previously in Figs 36(a) and 36(b).

As

the field produced by one of the loops reduces the

voltage on the cavity probe adjacent to the loop and directly opposite

it also

reduce. The phase difference between the maximum and minimum voltage

probes

(which are either adjacent or opposite the loops) stays fixed at 90

degrees but

the phase difference between a probe at maximum voltage and a probe 45

degrees

from it reduces considerably.

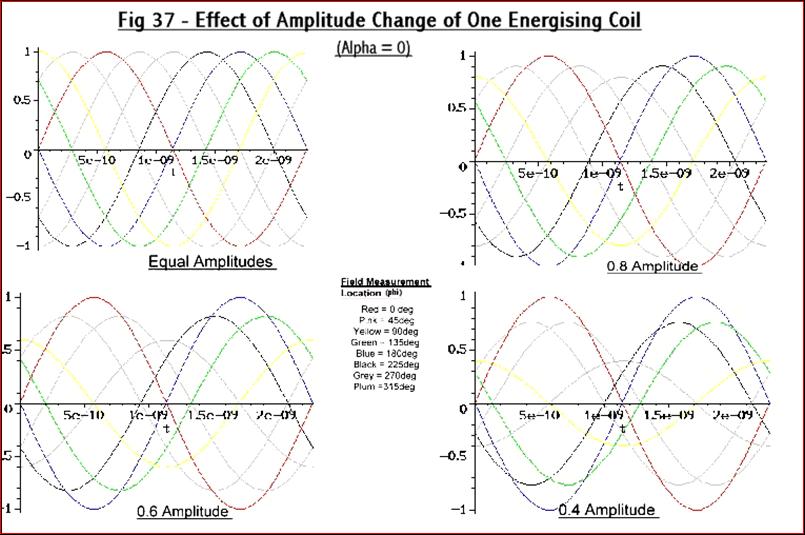

If

the amplitudes are the same but the phase

difference varies from 90 degrees, by the angle alpha, then the

measured fields

will be:-

In

this case when the phase difference between the

energizing coils deviates from 90 degrees it will affect the amplitude

as well

as the phase of the voltages measured at the top plate probes.

The

above two figures show the sort of effects that

are observed when tuning the cavity for a spinning field. If just two

cavity

probes are to be observed for the initial tuning then one technique is

to use

two probes physically spaced 45 degrees apart (probes 1 and 2) and

adjust for

equal voltages and 45 degree electrical phase displacement. Then check

two

probes spaced 90 degrees apart and opposite the energizing coils

(probes 1 and

3) to check that each of the two component fields are the same

magnitude.

The

above analysis illustrates the difficulty in

obtaining a set of readings in which all probe voltages are exactly the

same

magnitude and the phase difference between them is the same as their

physical

angular separation. This would only occur if the two component fields

were

absolutely identical in amplitude and have exactly 90 degrees phase

difference.

If this condition were not exactly met then a spinning field would

still be

produced but in addition there would be a small conventional stationary

field

superimposed on it.

Obtaining a Spinning

Field With Just One

The

above explanation for obtaining a spinning field

from two loops has for simplicity assumed that each loop only produces

a main

cavity mode. In practice the loops also produce a substantial second

cavity

mode at right angles to the main one. It was observed that the optimum

spinning

field was obtained not with the two loops rotated to the same angle but

with

loop 2 almost vertical and loop 1 almost horizontal. This means that

loop 1

would have been making only a minor contribution to the total cavity

field. The

most likely reason for this is that the second cavity mode produced by

loop 2

is providing a large portion of the required field it has previously

been

assumed loop 1 main mode would produce. The spinning field is still

being produced

by two fields at right angles and with a 90 degree phase difference but

the

source of each of these two fields is not solely its associated loop.

To

test this a further experiment was done with just

loop 1 energized but the cavity circularity was adjusted to bring its

main and

second modes to the same frequency to see if a spinning field could be

produced. For a spinning field it would require the main and second

modes to be

equal amplitude. Looking at Fig 32A(a) and Fig 32B(a) it can be seen

that for

the 4.5cm diameter loop used they very nearly are. There must also be a

90

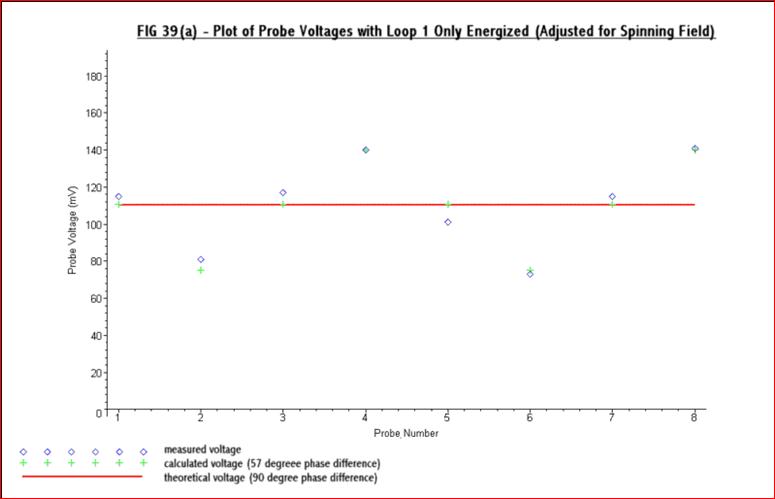

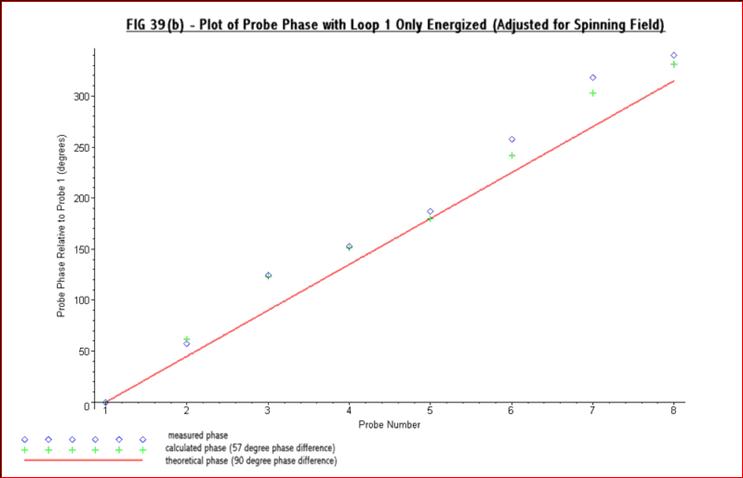

degree phase difference between them. Typical results obtained are

shown in Fig

39(a) and Fig 39(b) below:-

The

above figures confirm that just one loop is able

to produce a substantial spinning field. Fig 39(a) indicates that out

of a peak

probe voltage of 140mV the spinning field is just over 70mV. It

is

possible to re-plot equation 2, for the total field (i. e. Et = F(![]() +A

+A![]() )

), to give the

calculated phase difference and voltage at the probes. This has been

done on the

above figures and is shown by the green crosses for a phase error (α)

of

33 degrees. This is equivalent to a phase difference of 57 degrees

between the

main and second fields, assuming that they are the same amplitude. This

phase

error gives the best fit to the actual readings and so it is reasonable

to

assume that this is the phase error which existed when the test results

were

taken. It was found difficult to improve on this with just one loop

energized

as the only adjustment available was the circularity of the

cavity. It

does, however, illustrate the ease with which a limited amount of

spinning

field can be produced.

)

), to give the

calculated phase difference and voltage at the probes. This has been

done on the

above figures and is shown by the green crosses for a phase error (α)

of

33 degrees. This is equivalent to a phase difference of 57 degrees

between the

main and second fields, assuming that they are the same amplitude. This

phase

error gives the best fit to the actual readings and so it is reasonable

to

assume that this is the phase error which existed when the test results

were

taken. It was found difficult to improve on this with just one loop

energized

as the only adjustment available was the circularity of the

cavity. It

does, however, illustrate the ease with which a limited amount of

spinning

field can be produced.